Reverse Logistics Opens the Way for Packaging Recycling, Boosting Green Exports

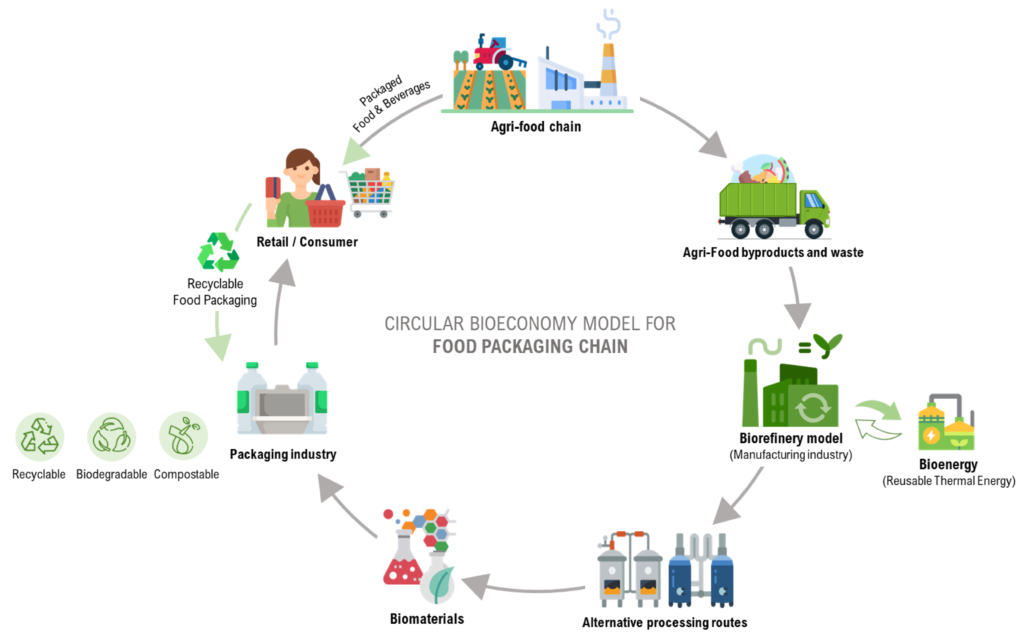

As major markets like the EU and the US increasingly focus on environmental standards, transitioning to eco-friendly packaging has become an inevitable trend. Reverse logistics is a technical solution for collecting, reusing, and recycling packaging; it is a key strategy helping Vietnamese businesses avoid being excluded from the fierce export competition.

As major markets like the EU and the US increasingly focus on environmental standards, transitioning to eco-friendly packaging has become an inevitable trend.

1. Reverse Logistics and the Importance of Packaging Recycling in Green Exports

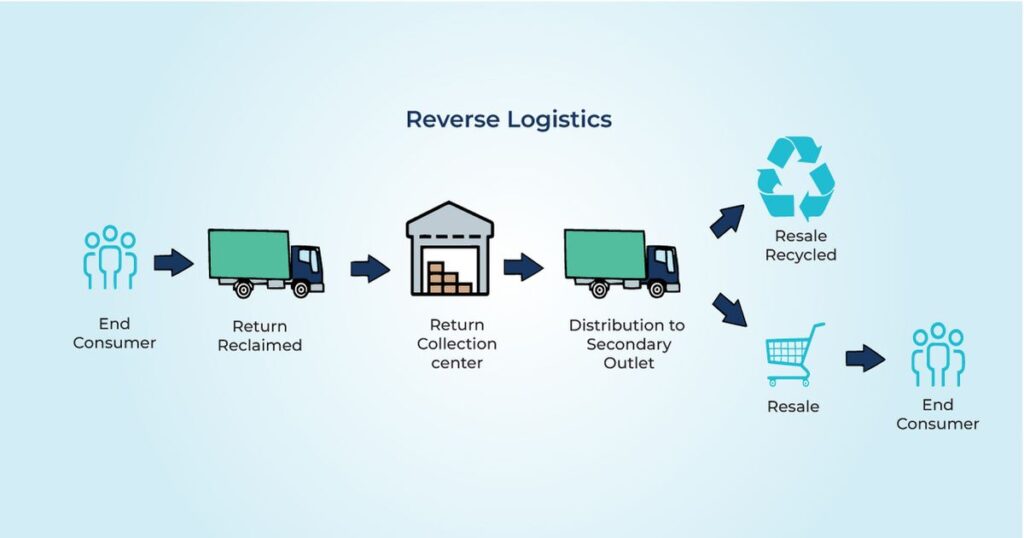

According to Rogers and Tibben-Lembke (1999), reverse logistics is the process of planning, implementing, and controlling the efficient flow of raw materials, semi-finished products, and related information from consumption points back to their origin with the purpose of recovering value or properly handling them. In simpler terms, reverse logistics, also known as recovery logistics, is the process of transporting used products or packaging from consumers back to their source or disposal locations for reuse, repair, recycling, or safe disposal.

As major markets continue to set stringent environmental requirements for imported goods, businesses must comply with regulations concerning carbon emissions, packaging recycling, and waste management in order to meet quality and origin standards. Therefore, reverse logistics and packaging recycling have become crucial factors in the export strategies of Vietnamese enterprises.

Reverse logistics and packaging recycling have become crucial factors in the export strategies of Vietnamese enterprises.

Mr. Nguyễn Duy Minh, Secretary-General of the Vietnam Logistics Business Association (VLA), when discussing regional cooperation for Vietnamese businesses towards green exports, emphasized five key issues that need to be addressed: infrastructure, human resources, logistics service providers, logistics service users, and institutional policy frameworks.

Especially, regarding two pillars, logistics service providers and consignees, Mr. Minh suggested that a green transformation model combined with digital transformation should be adopted as an important strategy to help Vietnamese businesses enter export markets and meet strict international standards.

2. Current Situation and Prospects for Packaging Recycling and Reverse Logistics in Vietnam

According to statistics, Vietnam consumed about 0.2 million tons of plastic in 1990, but by 2022, this number had surpassed 9 million tons. Data from Future Market Insight estimates that Vietnam’s plastic market will reach 10.92 million tons by 2024 and is projected to grow to 16.36 million tons by 2029.

Everage packaging made of aluminum has the highest average recycling rate at 77%, while glass bottles, PET plastic bottles, and multi-layer cartons have recycling rates of 45%, 4%, and 14%, respectively.

According to environmental and waste management consultancy Eunomia Research & Consulting (UK), more than 728,000 tons of beverage packaging in PET plastic, HDPE, PP bottles, glass bottles, and aluminum cans are released into the market annually. However, not all of these packaging materials are properly collected or recyclable.

Regarding plastic consumption, Mr. Nguyễn Thi, Head of the Legal Department of the Ministry of Natural Resources and Environment, has shown alarming growth, from an average of 3.8 kg of plastic per person per year in 1990 to 81 kg per person per year in 2019. Furthermore, when considering the application of plastics, the OECD has shown that the two sectors with the highest application rates are packaging and construction, with rates of 31% and 17%, respectively. These figures highlight the dominant role of plastics in consumption and infrastructure-related fields. Specifically, in Vietnam, Mr. Vũ Huy Hùng from the Information and Trade Promotion Department pointed out that the packaging and household plastic sectors lead in plastic application trends, with usage rates of 39% and 32%, respectively.

Most of the urban waste recycling activities in Vietnam are carried out by the informal sector, with collection rates ranging from 40% to 85%, depending on differences between rural and urban areas.

The recycling capability of various packaging materials varies. Beverage packaging made of aluminum has the highest average recycling rate at 77%, while glass bottles, PET plastic bottles, and multi-layer cartons have recycling rates of 45%, 4%, and 14%, respectively.

During recycling, material loss is unavoidable. However, aluminum cans have the lowest material loss rate, about 4%, while other materials like plastic lose 10%, and multi-layer packaging or cartons lose up to 28%. The main reason is that aluminum cans are made from a single material, whereas multi-layer packaging has a complex structure that makes recycling more challenging.

3. Reverse Logistics Opens the Way for Packaging Recycling, Boosting Green Exports -1

The reverse logistics process in packaging recycling involves a series of systematic activities designed to collect and process packaging after use

Reverse Logistics Process in Packaging Recycling

The reverse logistics process in packaging recycling involves a series of systematic activities designed to collect and process packaging after use. This process typically includes the following main steps:

Step 1: Collection

Gather used packaging or unsold, defective, or returned products and bring them to collection points. This crucial step determines the amount of packaging that can enter the recycling loop.

Step 2: Inspection and Sorting of Recovered Packaging

Inspect the quality of packaging and sort it based on various criteria such as material type, damage level, and reuse potential. It is then categorized into recyclable or non-recyclable materials.

Step 3: Processing

Depending on the condition of the packaging and recycling goals, there are various processing methods, such as direct reuse, repair, recycling into new materials, or safe disposal.

For non-recyclable products, they are turned into energy by being sent to factories for processing. Some factories use plastic to produce electricity, while others use it to produce other fuels such as diesel, mazut, or chemicals.

For recyclable products, after being sent to factories, plastics are cleaned, crushed, and turned into recycled plastic pellets. These pellets can then be used to make new products such as T-shirts, furniture, plastic bags, and bottles.

Waste Recycling Process

4. Reverse Logistics Opens the Way for Packaging Recycling, Boosting Green Exports -2

Reverse logistics operations are more complex than forward logistics due to several reasons: unpredictable demand, transporting from multiple points to a single point, and inconsistent goods quality and pricing.

4.1. Policies to Promote Reverse Logistics and Packaging Recycling

Decree 05/2025/ND-CP, effective from January 6, 2025, amends some provisions of Decree 08/2022/ND-CP guiding the Environmental Protection Law.

Under the new regulations, mandatory recycling rates are defined as the “minimum weight of products or packaging that must be collected and recycled according to mandatory recycling standards within the year of responsibility on the total weight of products or packaging produced or imported into the market during the year of responsibility.”

This rate is determined based on various factors such as product lifecycle, disposal rates, collection rates of products and packaging, national recycling goals, and socio-economic conditions of each period.

Notably, the mandatory recycling rate for each product or packaging type in the first three years is specified in Decree 05, and it will be adjusted every three years, gradually increasing to meet national recycling goals and environmental protection requirements. The Decree also specifies that producers and importers of products or packaging listed in the Annex must register their recycling plans and report recycling results. They are legally responsible for the accuracy of the information provided.

4.2. Benefits of Applying Reverse Logistics in Packaging Recycling for Green Exports

Packaging recycling helps lower raw material costs, especially when the price of raw materials rises.

Meeting International Standards: Many international markets, particularly the EU and North America, require imported products to comply with strict environmental standards.

Reducing Production Costs: Packaging recycling helps lower raw material costs, especially when the price of raw materials rises.

Building a “Green” Image for Businesses: Implementing reverse logistics demonstrates a company’s social responsibility in environmental protection, helps reduce pollution, and creates a “green” image in the eyes of consumers.

4.3. Lessons from Other Countries

Many countries and regions worldwide have introduced regulations in efforts to improve reverse logistics activities, monitoring, and checking companies’ practices in handling and recycling products.

The European Union (EU) has provided guidelines for waste from electrical and electronic equipment (WEEE), along with directives on restricted substances in electrical and electronic equipment (RoHS), passed in February 2003. This has driven companies to organize and manage collection activities for product returns according to regulations.

Japan has the “Extended Producer Responsibility” (EPR) model, which requires producers and importers to take responsibility for the entire lifecycle of their products, including post-consumption stages. Japan’s strict waste sorting system is also a crucial factor in enhancing the effectiveness of reverse logistics and packaging recycling.

European countries such as Germany, Finland, and Ireland have efficient packaging recycling systems. The bottle deposit system has helped these countries achieve beverage packaging collection and recycling rates exceeding 90%. Consumers must pay a deposit when purchasing bottled beverages, which is refunded upon returning the empty bottles.

Followed: Vietstock

Nguồn: https://vietstock.vn/2025/04/logistics-nguoc-mo-loi-tai-che-bao-bi-day-manh-xuat-khau-xanh-768-1294641.htm

Nguồn tham khảo:

- [1] https://itslogisticsvn.blog/logistics-nguoc-logistics-thu-hoi/

- [2] https://www.bsc.com.vn/tin-tuc/tin-chi-tiet/1188929-mo-loi-xuat-khau-xanh-de-doanh-nghiep-khong-bi-gat-ra-khoi-cuoc-choi-khac-nghiet

- [3] https://provietnam.com.vn/tin-tuc/bao-bi-chiem-phan-lon-rac-thai-nhua-doanh-nghiep-gap-rut-day-manh-tai-che/

- [4] https://thanhnien.vn/ty-le-tai-che-bao-bi-o-vn-va-cach-thuc-day-nen-kinh-te-tuan-hoan-1851487167.htm

- [5] https://provietnam.com.vn/tin-tuc/bao-bi-chiem-phan-lon-rac-thai-nhua-doanh-nghiep-gap-rut-day-manh-tai-che/

- [6] https://cantocan.com.vn/recyclingratevn/index_vi.html

- [7] https://thanhnien.vn/ty-le-tai-che-bao-bi-o-vn-va-cach-thuc-day-nen-kinh-te-tuan-hoan-1851487167.htm

- [8] https://itslogisticsvn.blog/logistics-nguoc-logistics-thu-hoi/

- [9] https://www.quanlynhanuoc.vn/2023/04/21/logistics-nguoc-trong-ban-le-mot-so-luu-y-va-dinh-huong-chien-luoc-toi-uu/

- [10] https://cebid.vn/mo-hinh-epr-cua-nhat-ban-tro-thanh-hinh-mau-cho-chau-a/

- [11] https://theleader.vn/bi-quyet-cho-ty-le-tai-che-tren-90-cua-cac-nuoc-chau-au-d13355.html

Operating under the motto of “Pioneering Quality,” Hoang Vuong consistently aims for sustainable and environmentally friendly packaging solutions. We proudly hold the following certifications: FSC Certification, GMI Certification, G7 Certification, ISO 9001:2015

With over 15 years of experience in the paper packaging industry and a solid brand reputation, Hoang Vuong is a leading private paper packaging enterprise in Vietnam, partnering with numerous major brands locally and internationally. We accompany your company on the journey of innovation, seeking differentiation through continuous improvement. Your success is both an achievement and motivation for us to continue innovating and maintaining professionalism.

- Address: 10/6C Street 10, Binh Hung Hoa A Ward, Binh Tan District, Ho Chi Minh City

- Mobile: 0908.863.965 (Mr. Le Hong Son)

- Phone: 028.62696129 – 028.22481926

- FAX: 08.62696032

- E-mail: havupackage@gmail.com

- Website: www.baobigiay.vn – www.hopcungcaocap.vn

- Fanpage: Hoang Vuong Paper Packaging Company Limited.